Mailbox:

info@hskcoltd.com

Mailbox:

info@hskcoltd.com

Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Email: info@hskcoltd.com

The New Energy Vehicle (NEV) and medical industries rely heavily on metal stamping manufacturers. For new energy vehicles or, more specifically, electric vehicles, metal stamping is a critical manufacturing method that helps produce a high volume of complex parts that comply with strict automobile specifications and guidelines. At the same time, metal stamping also helps manufacture high volume production of parts for devices in the healthcare industry.

With precision, quality, and size forming the significant requirements for components in these industries, metal stamping technology is considered crucial for their development.

Applications of Metal Stamping in New Energy Vehicles

Take a look at some of the major applications of metal stamping in producing new energy vehicles.

l Charging Pile Terminals

Charging pile terminals are the equipment needed to charge electric vehicles. The design for these EV charging piles requires many metal stamping parts. Metal stamping can help shape the precise components such charging piles require.

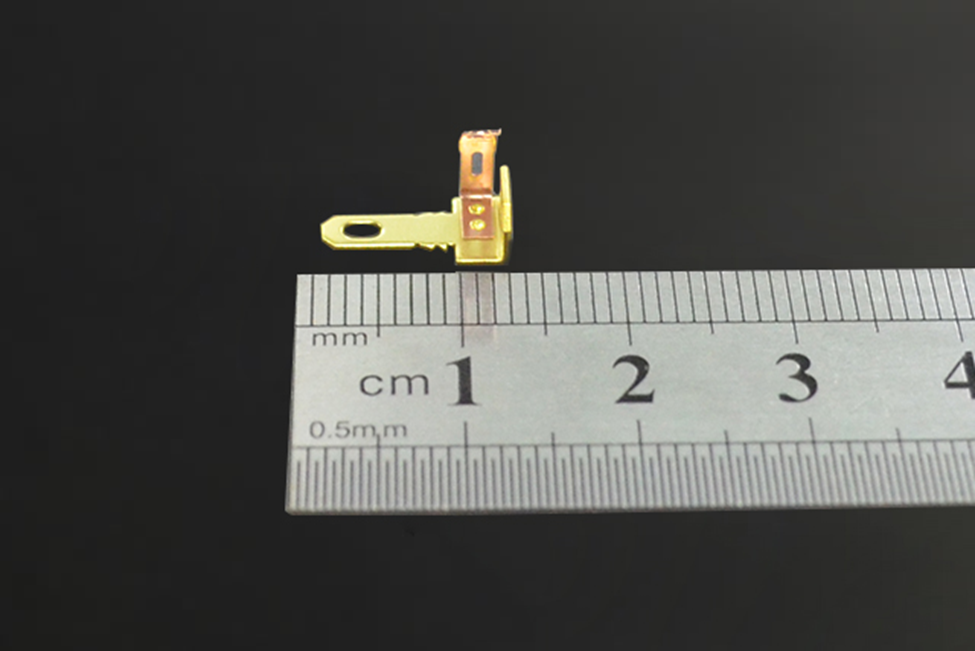

l Bayonet Hardware

The bayonet hardware is a type of electrical connector that helps the AC charging of electric vehicles. It can be broken down into several individual parts, such as pins and nuts. Manufacturers use metal stamping to form the exact precise shape and cut for your bayonet.

l Automotive Terminals

Automotive connector terminals are used to provide quick and simple connection points between one or more wires and headers. In vehicles, it helps connect the various electric parts within your car. Automotive metal stamping also helps manufacture these precise terminals.

l Automobile Camera gaskets

Gaskets or seals help to maintain a tight metallic joint across parts of your engine. Camera gaskets are miniaturized parts that help protect and seal any openings, including where the cables enter. Since they are meant to be as discreet as possible, metal stamping comes in handy. Metal stamping helps manufacture the right size of camera gaskets for your automobiles.

Applications of Metal Stamping in Medical

Take a look at some of the major applications of metal stamping in the medical industry:

l Gastrointestinal

Metal stamped medical devices are helping with the rapid growth of the medical industry. In the case of GI or gastrointestinal devices, we find many components that can be manufactured with precision using medical stamping. Gastrointestinal stents, for instance, are a common occurrence. Moreover, several surgery devices are also manufactured in this manner.

l Dosing Devices

Devices used to measure and administer liquid medications are also a core part of any healthcare setup. Metal stamping can help manufacture these dosage devices with precise sizing and measurements so dosages can be administered with complete accuracy.

l Measuring Microscopes

Measuring microscopes are a type of optical microscopes with precise target measuring capabilities. Measuring microscopes themselves require a number of metal parts which metal stamping can help manufacture with accuracy.

Why is Metal Stamping Crucial for These Industries?

Metal stamping is incredibly important for inexpensively producing highly accurate parts, an acute demand in these industries. Here are some significant reasons why metal stamping is crucial for the NEV and medical industries.

l Cost-Effectiveness

Metal stamping can prove to be incredibly cost-effective. This is because you can make changes to the production line as needed. Add as much automation, as much manual labor, and machinery as you desire. Choosing the right equipment and methodology can go a long way in saving your overall costs.

l Material Efficiency

Metal stamping is usually performed using specialized machinery and technology that can help efficiently manufacture high-volume or low-volume productions as needed. You can manufacture a large number of identical, high-quality parts at incredibly fast rates.

l High Precision Accuracy

One of the primary reasons why people prefer to use metal stamping is the level of accuracy and precision it offers. This is because metal stamping operations tend to rely on automated machinery and technology that offers precise, accurate results. For industries such as the medical and new energy vehicles industry that demand extremely precise results, metal stamping is the best way to go.

Hashimoto - the Professional Metal Stamping Manufacturer

If you are looking for a reliable metal stamping manufacturer, consider working with Hashimoto. Here’s why!

1. Advanced Technology

Hashimoto is known for employing the latest state-of-the-art technology in its metal stamping processes. We have over 40 punching machines and optical grinding machines in our production line that can take over all types of productions accurately and efficiently.

2. One-Stop Manufacturing Service

Hashimoto serves as a one-stop manufacturer for all your metal stamping needs. Not only do we develop the die design, but we will also handle the mass manufacturing of your components before they are ready for assembly.

3. Years of Experiences

Finally, Hashimoto has the experience needed to handle all types of metal stamping projects. Established in December 2002, we have established the company as the trusted voice when it comes to metal stampings.

About Hashimoto

Hashimoto is one of the leading metal stamping manufacturers today. Today we offer our clients a wide range of metal stamping parts and product manufacturing services at an incredibly affordable cost! That’s not all; we are ISO9001, ISO14001 and IATF16949 certified, meeting the industry standards of a quality metal stamping manufacturer.

Contact us now for more metal stamping information!

Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Email: info@hskcoltd.com

Follow us

Copyright ? 2021 Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Mailbox